KLA R50 Four-probe Resistivity Meter

KLA R50 Product Introduction of Four-Probe Resistivity Meter

KLA R50 Four-probe resistivity mapping systemisKLAProducts of the resistance testing series. Resistance measurement and monitoring are of great significance to any industry that uses conductive films, ranging from semiconductor manufacturing to flexible electronic products required for wearable technology.KLA R50 Four-probe resistivity meterIt can be involved in the measurement fields such as the uniformity distribution of metal films, characterization of ion doping and implantation, distribution of film thickness and resistivity, as well as non-contact film thickness.

KLA R50 Advantages of the four-probe resistivity meter

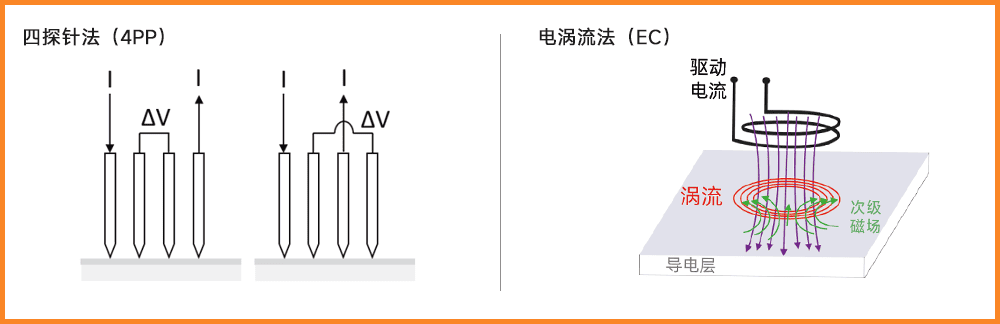

Contact four-point probe(4PP)And non-contact eddy currents(EC)Configuration;

100mmZItinerary,High-precision control

Conductor and semiconductor thin-film resistors10Applicable within a range of several orders of magnitude;

Custom editing of test points,Including rectangular, linear, polar coordinates and custom configurations;

200mmXYElectric platform;

RSMapperThe software is flexible and easy to use;

CompatibilityKLAAll thin-film resistance measurement probes;

KLA R50 The measurement principle of the four-probe resistivity meter

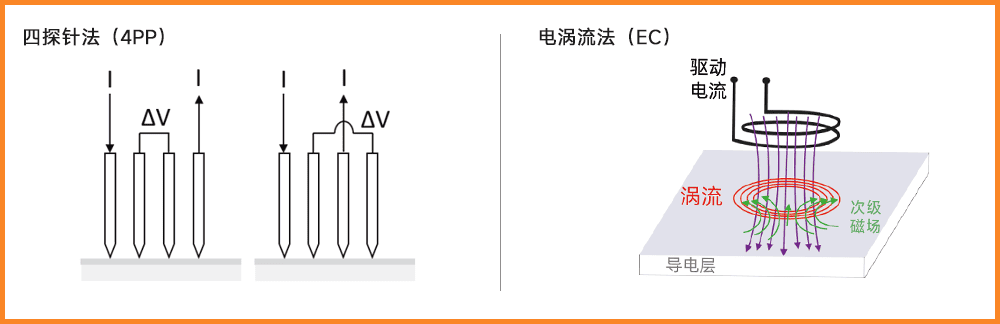

Four-point probe(4PP)The probe composed of four conductive probes contacts the surface of the conductive layer with a controllable force,Among them, there is a non-conductive barrier layer between the measured conductive layer and the substrate. The standard probe configuration for measurement is to apply current between two outer probes and measure voltage between two inner probes. When measuring thin-film resistance, the thickness of the conductive layer should be less than the distance between the two probes1/2.KLAinR50Four-probe resistivity meterWe have developed a dual-mode technology, which enables the measurement of voltage on interval probes and is equipped with dynamic boundary effect correction and probe spacing error compensation functions.KLAIt provides a rich variety of probe types to apply and optimize the characterization measurement of different surface materials, and can be used for almost any conductive film or ion-implanted layer.

Electric eddy current(EC)Non-contact conductive film measurement technology. A time-varying current is applied through a coil to generate a time-varying magnetic field. When this magnetic field approaches a conductive surface, an induced time-varying current (eddy current) will be generated on that surface). These eddy currents, in turn, generate their own time-varying magnetic fields, which couple with the probe coil and produce signal changes proportional to the resistance of the sample.KLASpecialECThe technology, with a single probe located at the top of the sample, can dynamically adjust the height of the probe at each measurement point, which is quite important for the accuracy and repeatability of the measurement.ECThe method is not affected by the size of the probe or surface oxidation, and is very suitable for softer ones or those that are not applicable4PPSamples measured by the contact method.

Industry application of KLA R50 four-probe Resistivity Meter:

Semiconductor | "Tablet andVR"Display | Compound semiconductor | Advanced packaging |

Solar energy | Printed circuit | Wearable devices | Conductive material |

Product application of KLA R50 Four-probe Resistivity Meter:

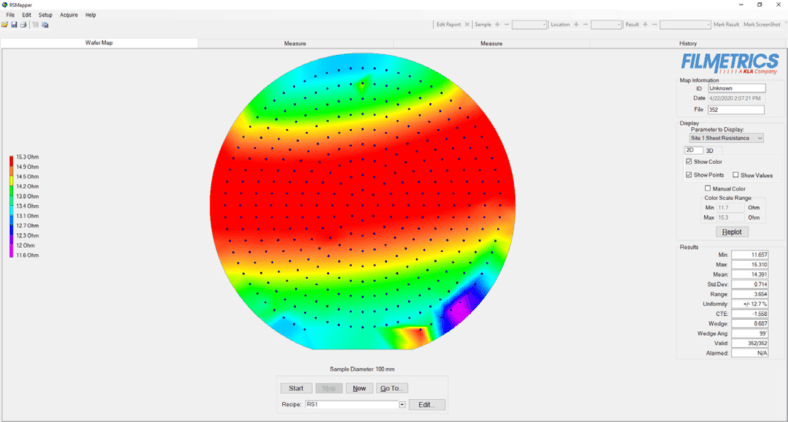

I. Uniformity of Metal Films

The uniformity of the thin-film resistance of metal films is quite important for ensuring the performance of components, and most metal films can pass through4PPandECMake a measurement.ECRecommended for thicker, highly conductive metal films4PPIt is suitable for thinner metal films(>10Ω/sq)But in any case,4PP/ECAll of them show a high degree of correlation, thus ensuring that accurate results can be obtained by using any method.KLA R50 The resistance distribution diagram of the four-probe resistivity meter can characterize the uniformity of thin films, deposition quality and other process fluctuations.

Ii. Characterization by Ion Implantation

4PPThe method is the standard measurement technique for evaluating ion implantation processes. After thermal annealing, the ion implantation distribution can be tested to identify lamp faults and wafers/Hot and cold spots caused by poor platform contact or changes in injection dosage. For the silicon ion implantation layer, the thermal annealing process is necessary for activating the doped ions.

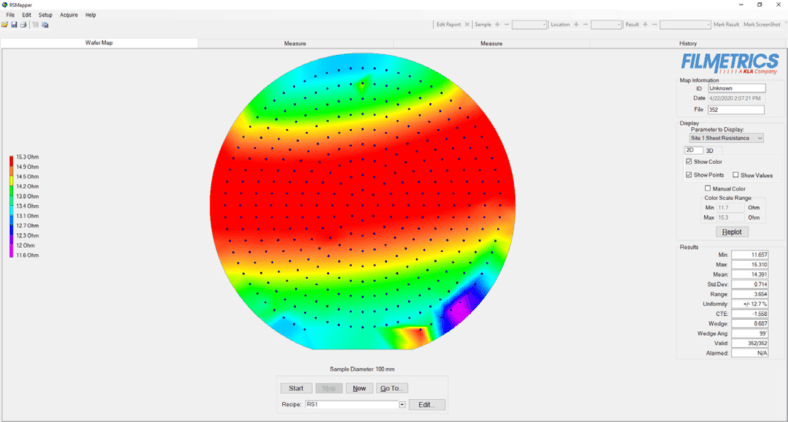

Iii. Film Thickness/Resistivity/Film Resistance

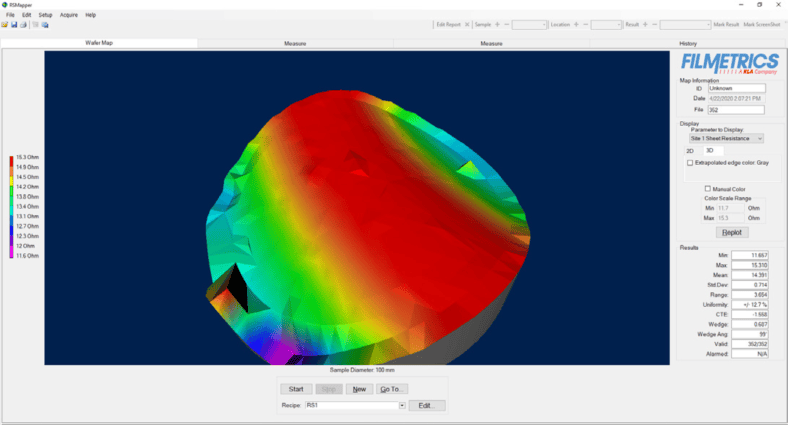

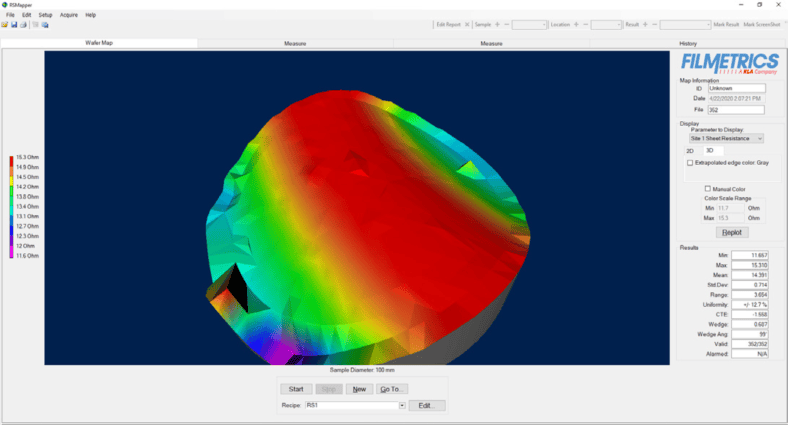

Through the collected wafer data,KLA R50 Four-probe resistivity meterIt is possible to draw distribution graphs of thin film resistance, thin film thickness or resistivity. By inputting the resistivity of the material,The film thickness distribution can be calculated and displayed;Or by inputting film thickness data,Then the resistivity distribution can be calculated.

Iv. Data Collection and Visualization

KLA R50 Four-probe resistivity metertheRSMapperThe software combines data collection and powerful analysis functions, featuring an intuitive visual interface. It can be used both on the device itself and offline. The various coordinate layout tools that come with the software can help users easily set data measurement points.

Product parameters of KLA R50 Four-probe Resistivity Meter:

ZScope | 60mm | ZPlatform type | "Automatic |

X-YPlatform type | "Automatic | Maximum load-bearing capacity of the sample stage: | 2.5 kg |

Inclined sample stage | Plus or minus 5 °Manual |

|

Electrical properties |

| R50-4PP | R50-EC |

Repeatability of measurement points | < 0.02% | < 0.2% |

Accuracy | Plus or minus 0.2% | Plus or minus 1% |

For more parameters, please contact us |

Measurement diagram of KLA R50 Four-probe Resistivity Meter: